1

Clients

1

Projects

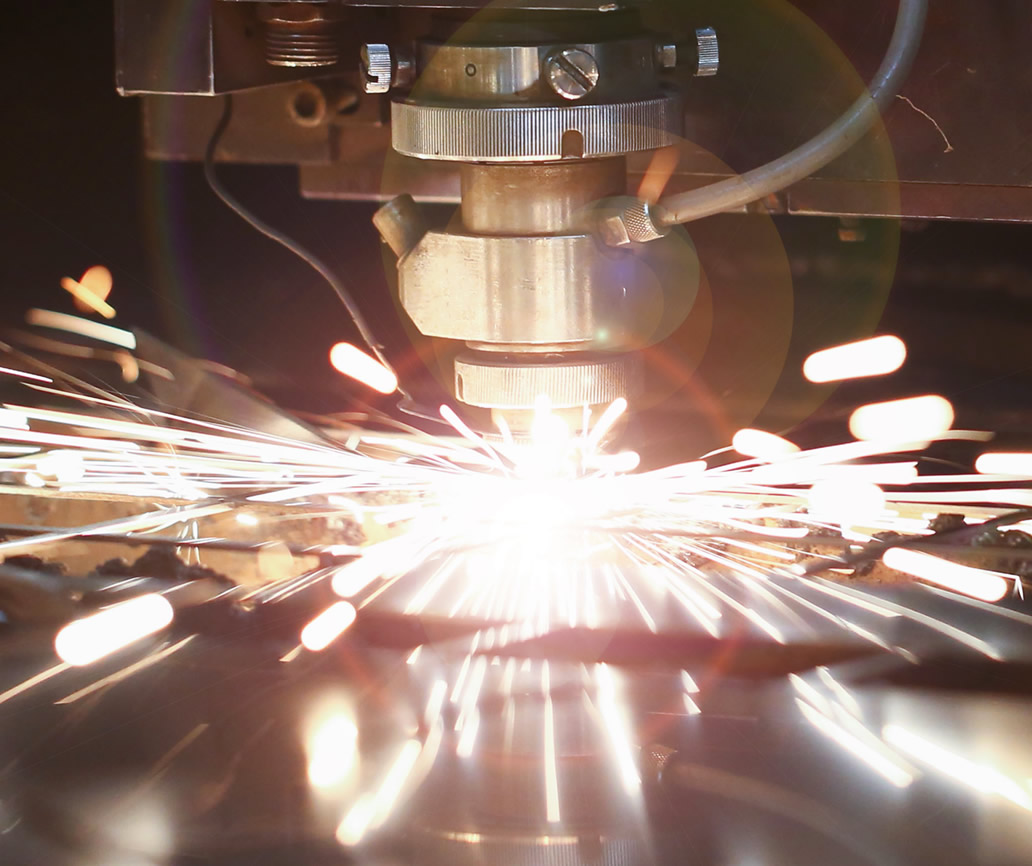

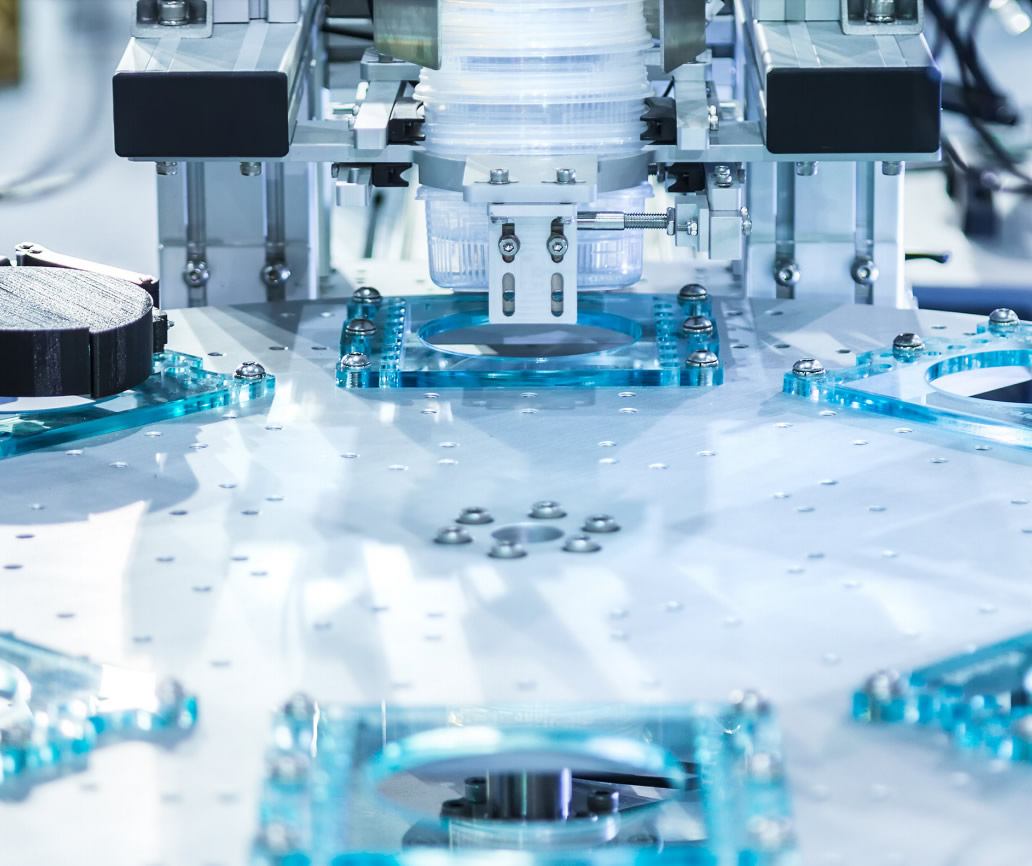

Our Hardware services

We design, build and test the electrical equipments required by the application, we offer to our customers a complete industrial automation solution.

Drives and power circuits

Electromechanical or advanced Safety

Smart devices

Bus network design

Third party machines integration

Our Software development service

PLC standard & safety

DRIVE MOTION

HMI intuitive

SCADA

Robot programming with advanced Safety

1

Code lines

1

Drives

1

Movel robot statements

1

HMI & SCADA UI

Our Support services

In addition to ensuring the support for each of our projects, we can also intervene on automation solutions made by third parties: the best way for our new customers to know us straight away.

Retrofit obsolete hardware

Problem solving

Quickly on site

Production continuity

Third parts software integration

Takeover an ongoing project during commissioning

Some Industries of our customers

Welding

Assembly

Paper goods

Handling & Automatic Warehouse

Slitting lines

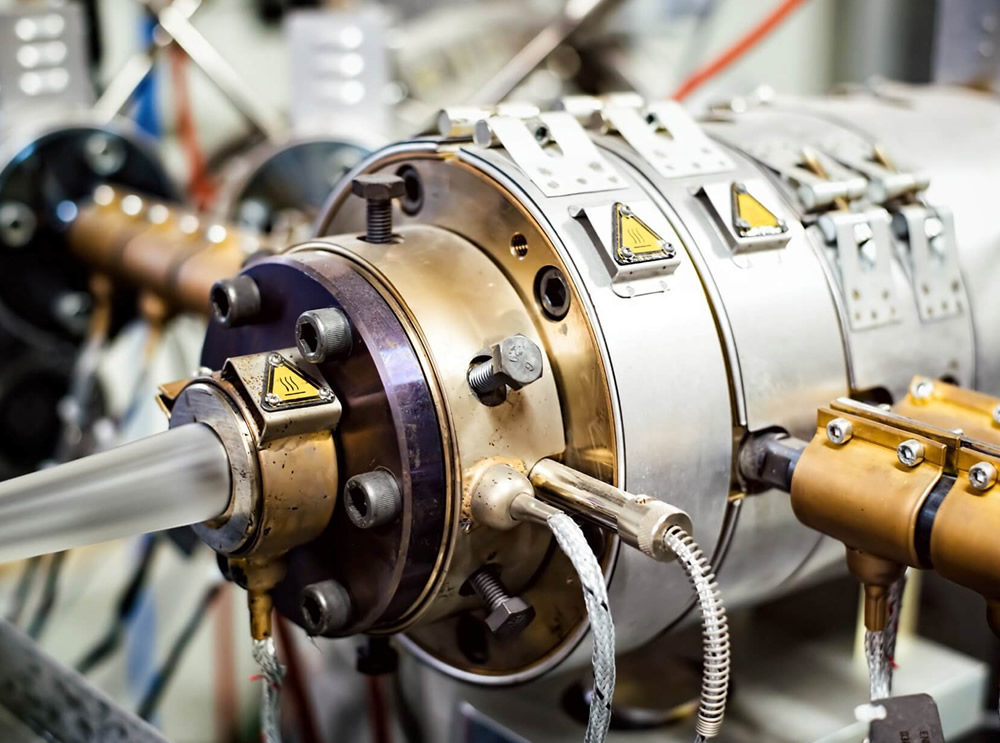

Plastic Extrusion

Food

Grinding

Industry 4.0 & Smart MES 4.0

Our customers and we face the digitalization challenge with our Smart MES 4.0 that connects the management to the shop floor. With our OEM constructors, we create both an Industry 4.0 Ready solution for the machine itself than a complete MES solution.

Connection between management and production

Smart MES 4.0 is a production management system applicable to multiple sectors, consisting of software modules and workstations (touch screen) installed in the production area to interact with machines and operators.

The goal is to improve the efficiency, the flexibility and the organization of production to improve the quality of the business..

In the office, the manager or the people in charge plan the work and monitor its progress by evaluating the performances of the production process. Thanks to the direct connection with the production, everything is under their eyes for the complete control.

Software that creates value